The structural characteristic of a non-independent suspension system is that the wheels on both sides are connected by a single integral frame, and the wheels and axles are suspended below the frame or body through an elastic suspension system. Non-independent suspension systems have advantages such as simple structure, low cost, high strength, easy maintenance, and small changes in front wheel alignment during driving. However, due to their poor comfort and handling stability, they are basically no longer used in modern cars, and are mostly used in trucks and large buses.

A transverse arm suspension system refers to an independent suspension system in which the wheels oscillate within the transverse plane of the vehicle. Based on the number of transverse arms, it is further divided into double transverse arm and single transverse arm suspension systems. Single transverse arm systems have advantages such as simple structure, high roll center, and strong anti-roll capability. However, with the increase in the speed of modern vehicles, an excessively high roll center can cause large changes in wheelbase when the wheels bounce, resulting in increased tire wear. Furthermore, during sharp turns, excessive vertical force transfer between the left and right wheels occurs, leading to increased rear wheel camber, reducing rear wheel lateral stiffness and causing severe high-speed tail-swing.

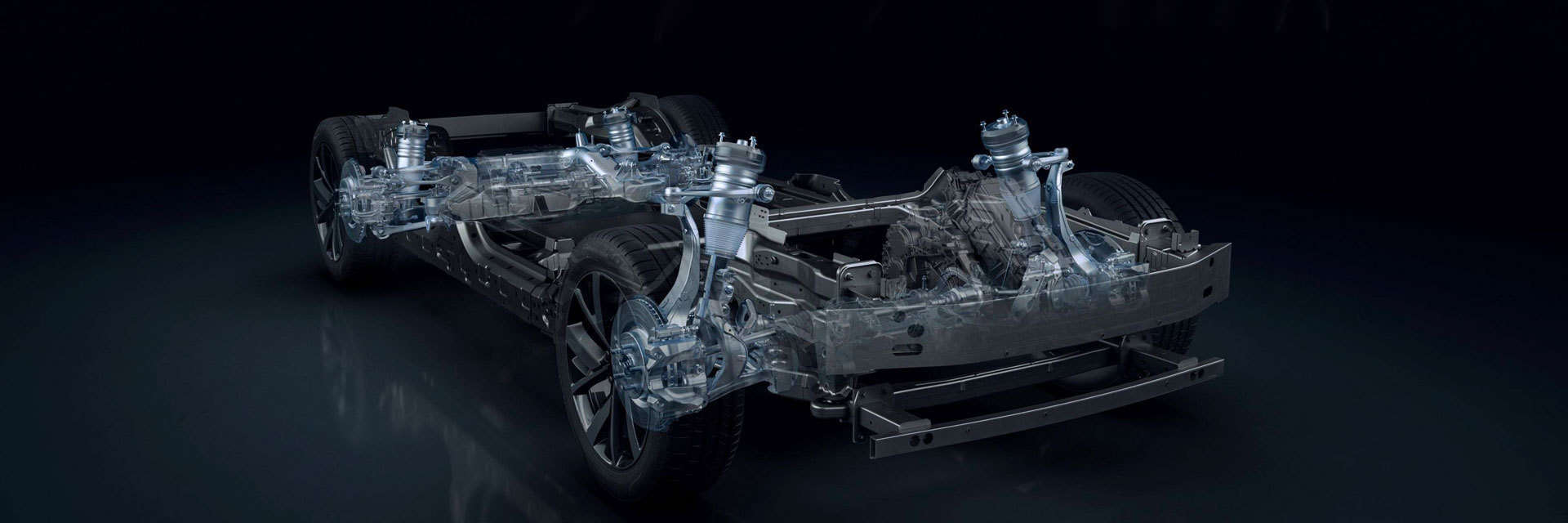

Double wishbone suspension is widely recognized as one of the best for handling, and it's used in the vast majority of performance cars and even F1 cars. It is also known as double A-arm suspension or double wishbone suspension and is a type of double wishbone suspension. Structurally speaking, double wishbone suspension can be considered the strongest independent suspension.

Rubber joints, as crucial pipeline components, play a significant role in oil pipelines. Their excellent elasticity and flexibility allow them to effectively absorb vibrations, compensate for pipeline displacement, and reduce noise, thus improving the reliability and durability of the entire oil transmission system. As a professional manufacturer in the field of high-end rubber joints, our rubber joints possess characteristics such as high efficiency shock absorption, high temperature resistance, and corrosion resistance, enabling them to adapt to various complex working conditions. For example, our rubber joints maintain excellent shock absorption even when facing high-frequency vibrations and remain stable under high temperatures and corrosive media.

In the petrochemical industry, quality control of hose installation and construction is crucial. Before construction, it is necessary to strictly follow the drawings, ensuring the use of appropriate materials and accessories. During construction, detailed construction records should be compiled, and each section of the pipeline should undergo rigorous quality inspection. In pipeline welding construction, operations should be strictly performed in accordance with welding standards, and non-destructive testing should be conducted on the weld surface to ensure that the welding quality is qualified. In addition, pipeline corrosion protection is also very important, requiring the selection of appropriate anticorrosion materials and application in accordance with standards to improve the service life and stability of the pipeline.

Mining methane rubber hose solutions, suitable for methane extraction and other mining media transportation in coal mines. This hose has good bending performance, anti-static, flame retardant, wear-resistant, corrosion-resistant and other characteristics, especially suitable for coal mine methane extraction systems, borehole sealing and other fields. Its customized service can adjust the pipeline Size and performance parameters according to customer needs, ensuring perfect matching with specific usage scenarios, improving work efficiency, and reducing operating costs.