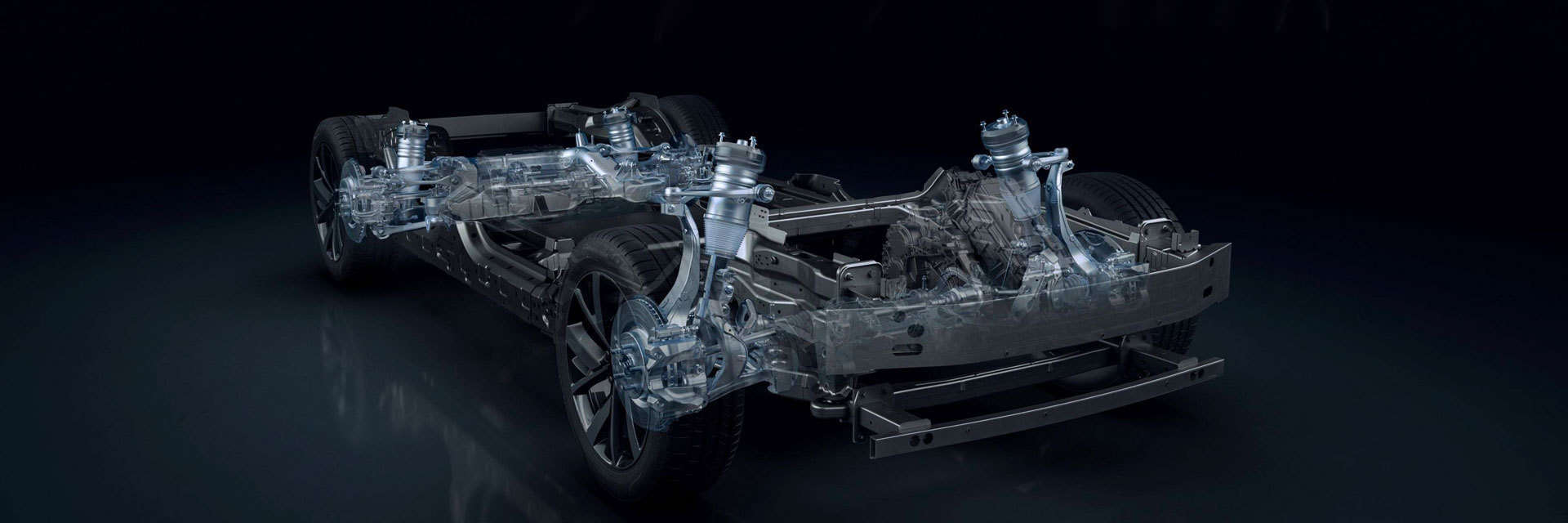

Generally speaking, vehicle suspension systems are divided into two types: non-independent suspension and independent suspension. In non-independent suspension, the wheels are mounted on both ends of a rigid axle. When one wheel bounces, the other wheel also bounces accordingly, causing the entire vehicle body to vibrate or tilt. In independent suspension, the axle is divided into two sections, and each wheel is independently mounted on the chassis with a coil spring. When one wheel bounces, the other wheel is unaffected, and both wheels can move independently, improving vehicle stability and comfort.

A device used to buffer vibrations and absorb energy. Shock absorbers use pressure generated by liquids or gases inside to drive the valve body, absorbing vibration energy and mitigating vibration effects. Air pressure shock absorbers generally have a higher Price than those using oil pressure. A small number of high-priced shock absorbers use a shared liquid and gas pressure design.

The rod used to connect the wheel to the chassis. The connecting rod can be a simple round rod or a structure made of steel plate. After understanding the basic elements of the suspension system, you can also design a suspension system like an automotive engineer.

The structural characteristic of a non-independent suspension system is that the wheels on both sides are connected by a single integral frame, and the wheels and axles are suspended below the frame or body through an elastic suspension system. Non-independent suspension systems have advantages such as simple structure, low cost, high strength, easy maintenance, and small changes in front wheel alignment during driving. However, due to their poor comfort and handling stability, they are basically no longer used in modern cars, and are mostly used in trucks and large buses.

A transverse arm suspension system refers to an independent suspension system in which the wheels oscillate within the transverse plane of the vehicle. Based on the number of transverse arms, it is further divided into double transverse arm and single transverse arm suspension systems. Single transverse arm systems have advantages such as simple structure, high roll center, and strong anti-roll capability. However, with the increase in the speed of modern vehicles, an excessively high roll center can cause large changes in wheelbase when the wheels bounce, resulting in increased tire wear. Furthermore, during sharp turns, excessive vertical force transfer between the left and right wheels occurs, leading to increased rear wheel camber, reducing rear wheel lateral stiffness and causing severe high-speed tail-swing.